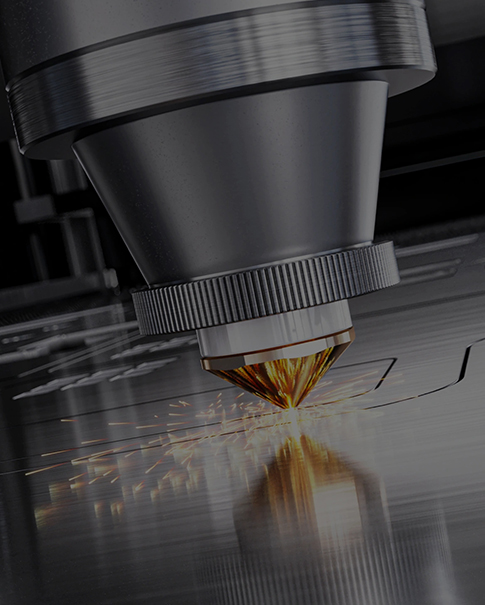

産業が構造物の大型化と重量材料の軽量化を進めるにつれ、超高出力ファイバーレーザーの需要は急増し続けています。中厚板を扱うメーカーにとって、PENTA LASERの80kW切断システムは、切断速度、エッジ品質、そしてコスト効率の革新的な組み合わせを提供します。

厚板切断に高出力が重要な理由

中厚鋼板、特に30mmから70mmの鋼板を切断するには、単なる力ではなく、インテリジェントな制御が必要です。80kWのレーザー出力を備えたこのシステムは、深い浸透と安定したエネルギー供給を実現し、極厚軟鋼でも滑らかで明るく、スラグのない切断面を実現します。

従来の低出力システムと比較して、高出力レーザー切断は次のようになります。

はるかに速い切断速度を実現

テーパーと熱変形を軽減

研削や研磨などの二次加工を最小限に抑えます

これは直接的にスループットの向上と生産コストの削減につながります。

よりスマートなガス、よりクリーンな削減

PENTAの高出力カッターの際立った特徴は、独自の混合ガス切断技術です。窒素と空気をリアルタイムの比率制御で混合することで、純窒素への依存を大幅に低減し、厚いステンレス鋼の切断をより経済的に行うことができます。

その結果、ステンレス鋼のきれいなエッジ品質、軟鋼の優れたカーフ制御、大量生産における大幅なコスト削減が実現しました。

産業製造における新たな標準

造船から建設機械、圧力容器から重機まで、この80kWのパワーハウスはあらゆるプレートにスピードと精度をもたらします。PENTAの高度なモーションシステムとソフトウェアと組み合わせることで、最も過酷な環境でも安定した長期性能を発揮します。